-

Ajhineh formwork makers company

Ajhineh Formwork makers Company is one of the most successful companies in the field of construction of steel concrete and steel structures in Iran. This honour is the result of the team's creative and committed team as well as the trust of our customers.

-

Design of steel concrete with the best of Iran

The unique design method of the project in the implementation of projects and the presence of high-quality creativity in the design of concrete steel formworks has been a significant development of the complex during its 10-year period. After gaining great titles and honours in the past years, we hope that we will be able to earn more honours by serving our dearest country and are waiting for your loved ones.

-

Products

To view each product, select item

-

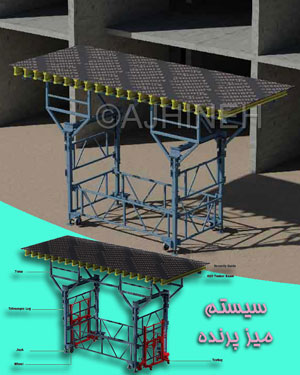

Newjersy formworkTunnel linningTunnel formworkExposed formworkSlip formI-Beam formworkTableform

-

Nanoflex formworkmodular formworkroof propCircular formworkManhole formworkShoringAccessories

-

Ajhineh Customers

The most trusted brands that have trusted us:

- National Standard

-

Exact timing

- Creative Ideas

- Unique Design

- Flexible Design

-

Briefing

-

Phone Support

- No extra Costs

- Customer Friendly

- Video Training

Design your project by the Ajhineh

-

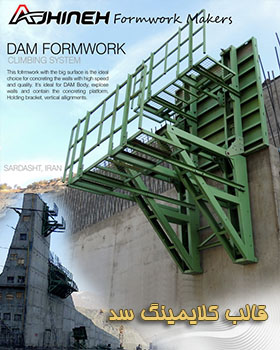

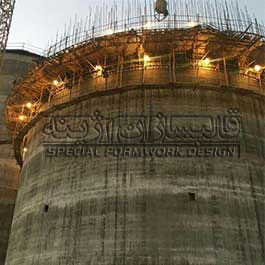

Special Formwork Design

Special Formwork Design

Designing custom formworks tailored to your project needs brings to you the design and technical engineering team of Ajhineh, providing creative ideas for speed and cost savings. If you need special templates, you can use the free consultation of the Ajhineh Team.

Fastest Time

Low budget 1 USD

-

Modular layout layout

Modular layout

Estimating the cost of the mold and knowing the size of the mold and the way layout templates is the most important step in calculating the cost of the contractor. But to run these calculations, you need a designer, an appropriate calculator and guide. The alarm can be a surefire guide for you to run your gigantic project.

Fastest Time

Free Budget Free

Post tension aided

-

PC-wire CNC cutter (Aryo-CUT)

Supply of consumable parts of railway sleeper formwork is always the most important problem for the production managers of this sector. With a CNC automatic hank opener machine and CNC cutter, each cutting speed of 6 seconds, with a precision cutting far superior to European machine ones, it has taken a major step in the self-sufficiency of the rail industry in the field of sleeper production.

Sleeper wire aryocut

-

T-beam formwork

Using the technology of the world in designing and manufacturing concrete formworks, the mass production of prefabricated concrete has been produced in such products as sleepers and T-beam, joists and slabs for the Ajhineh. Precision molds with accuracy of up to 0.1 mm and long life-spans make use of the high quality waterproof colors and materials used to justify the purchase of these formworks.

Pretension mold

-

Sleeper Pc-Wire neck machine

Along with the massive railway sleeper manufacturers, especially in new products, such as the 30-ton sleepers, the Ajhineh Company has produced 7 and 8 mm Pc-wire automatic necking machine and achieving the shortest production time among European neck machines. It makes it easy to achieve self-sufficiency in the traversing industry.

wire neck machine

Ajhineh Special Products

-

4.0612

New jersey integrated formwork

New Jersey formwork products with integrated body without any seams in concrete with cast iron joints ...

-

-

1.052

Railway Sleeper formwork

For the first time in Iran, the railways sleeper formworks with precision of 0.1 mm by the ...